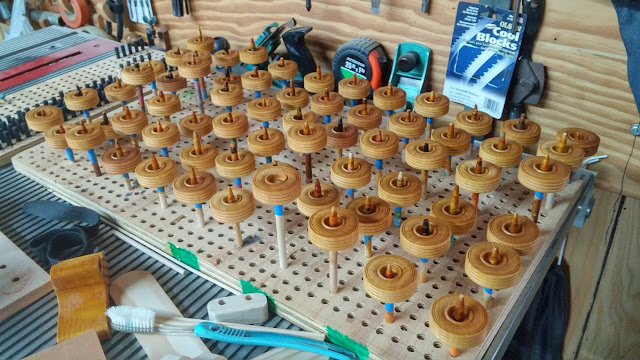

20240616-161533 Toymakers Shop - Tow Truck - Wheels - Purple - Amber Shellac: The Perfect Finish for Toy Wheels

My Five Truck Fleet When finishing toy wheels, I use Amber Shellac. It provides a beautiful, warm appearance and has practical benefits that make it ideal for kids' toys. One of the main reasons I favor shellac is that it doesn't mar the surfaces where the wheels roll. Unlike flat black paint, which can sometimes rub off and leave those pesky black marks behind, shellac stays put. The wheels I work with are typically made from end grain, which tends to soak up a considerable amount of shellac. There have been times when the shellac has soaked through the wheel. Shellac sprays beautifully straight from the can, but I prefer to apply it with a brush on the wheels. This method is less messy and gives me more control over the application. One common issue with dipping and spraying is that shellac can inadvertently get into the center holes of the wheels. Shellac inside the axle hole is crucial, as it can lead to glue failure when it comes time to attach the wheels to wooden ax...