This isn't a how-to or tutorial. Although in hindsight, it could have been if I had taken the time to take a bunch of photos.

This all started when I was cutting a project on my scroll saw, and it suddenly began making a knocking sound and vibrating badly. So bad that the blower tube was bouncing off the table. Slowing it down very slow let me finish what I was doing.

After some troubleshooting with tech support, I determined that the noise and vibration were caused by an accumulation of wear in the various bearings. There are eleven bearings in this saw.

I could have ordered parts one or two at a time until I found the right part, but since we are fast approaching Christmas I bought complete assemblies and replaced all the moving parts except the motor.

The photos were nearly unusable. Some things were completely missing. There were no instructions for removing and replacing the front rocker arm assemblies. The instructions would tell you to loosen a screw when what they meant was to remove the screw. Also, they didn't tell you about the four other screws you had to remove. I knew I was in trouble when I read the part that said to use an adjustable wrench. The instructions were obviously written by someone who already knew how to do this and not tested or proofed by a person who had never done it. The instructions told you how to take it apart but very little about how to reassemble every thing.

You can put the assembly in upside down. I'm real good at taking this saw apart now.

I knew there was going to be trouble when I read the part about using an adjustable wrench. Adjustable wrenches are for using on the occasional odd size fastener or fitting you might run across. I would never use an adjustable wrench to work on an $800 tool. It is to easy to break or round off a fastener that you can't easily replace. I have several, but they stay on the tool board and only get used as a last resort. If you want to do quality work, you use the right tools.

Why do they make things with a mix of metric and SAE fasteners? I spent way to much time trying to figure out which wrench to use. Especialy the cap screws.

Then there was my usual dropping parts and crawling around the floor looking for them. One thing I learned while searching for a tiny part was that my DeWalt Spotlight (DCL043) works great for finding parts. It lights up my floor like daylight.

The saw runs great now. I don't know if it is like new since I bought it used. This is the second saw I purchased used. My next saw will be a new one. Both of the scroll saws wound up needing to be refurbished. This one (EX21) wound up, costing me almost as much as buying a new one. My other saw is an older RBI Hawk that I purchased for $100 and spend $200 on, so it was still a bargain of sorts.

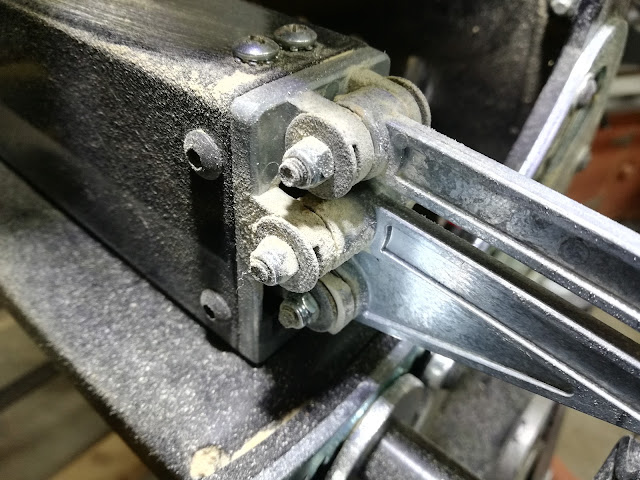

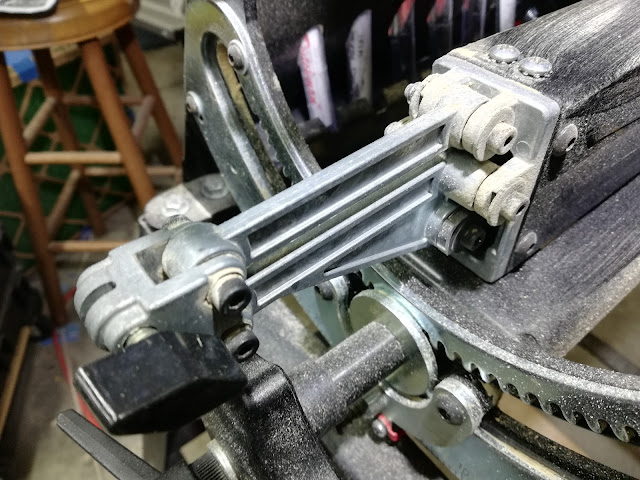

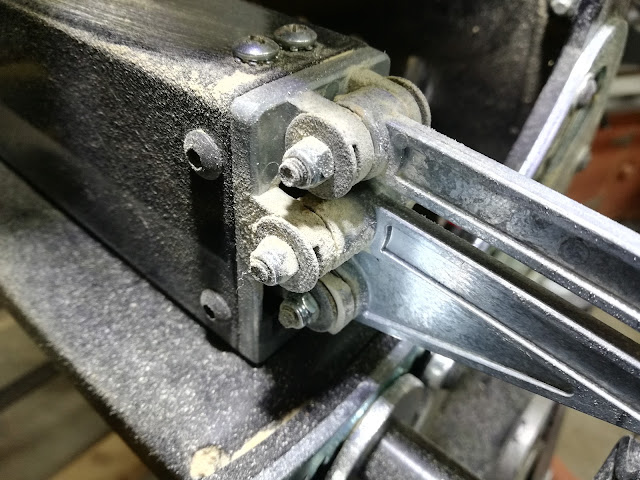

I didn't take many photos these were taken so I could see how to put things back together.

--

No comments:

Post a Comment