|

| Several versions of the peg board used in my shop are 3/4-inch plywood, 3/4-inch plywood with hardboard backing, lazy susan, and 3/4-MDF with hardboard backing. |

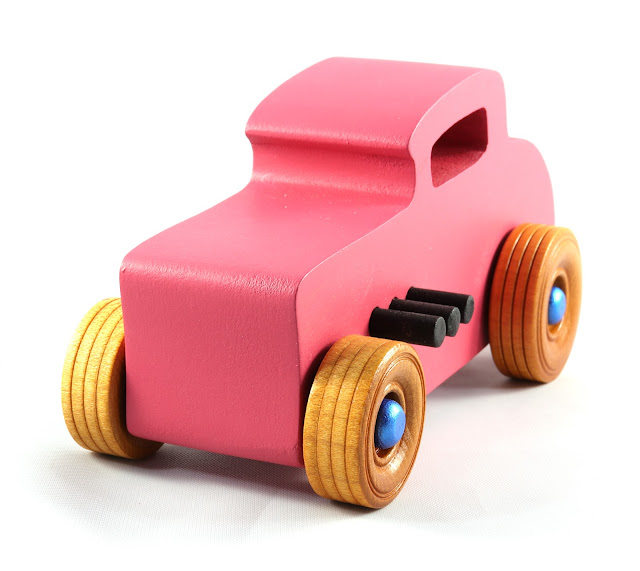

As a toy maker, I rely on my pegboards for painting and finishing my toys. But over the years, I've learned that not all pegboards are created equal. In this post, I'd like to share my journey of experimenting with different materials and designs to find the perfect pegboard for my needs.

My first attempt at a pegboard was made from thin, narrow wood. While it looked nice, I quickly realized that the holes were spaced too far apart, and the wood needed to be heavier to prevent tipping when loaded with toy parts. So, I switched to 3/4-inch BC plywood and drilled the holes almost all the way through. The plywood worked better, but I still found that the board would tip if I tried to hang anything too heavy. It needed to be broader, heavier, and have deeper holes.

Next, I tried drilling through the plywood and gluing it on a hardboard back. This design provided more support and stability, but I needed a better solution. Eventually, I tried using 3/4-inch MDF and hardboard, my favorite combination. The MDF is flat, heavy, cheap, and easy to work with, making it the perfect material for my pegboard needs.

One of my pegboards is even mounted on a lazy susan so I can spin it around, though I have yet to find this particularly useful in my toy-making process. I plan to try some ideas I have later.

Overall, my journey with pegboards has taught me the importance of experimenting and finding suitable materials and designs for my specific needs. Whether you're a toy maker or any other type of DIY enthusiast, I hope that my experiences can serve as a helpful guide in your pegboard endeavors.

Note: I still use all but the first pegboard I made and have made several others for particular purposes.