Building this tow truck is a fun and engaging project for DIY enthusiasts, but it can also be challenging. One of the most critical steps in constructing a tow truck is cutting the space for the tow hook, which can be a tricky task.

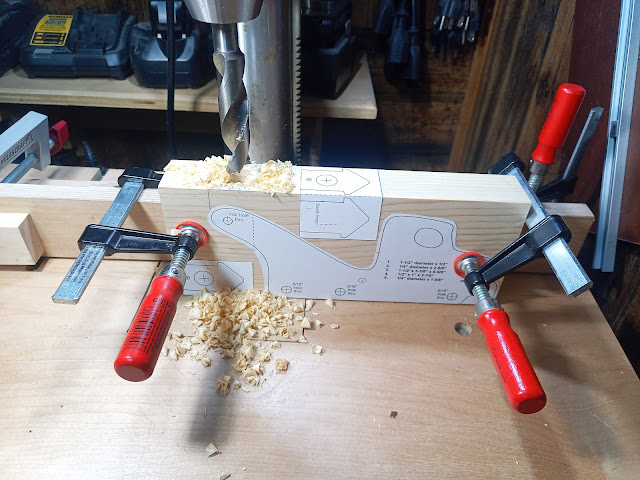

Over the years, I have experimented with various methods to cut the space for the tow hook, and drilling the 3/4-inch hole before cutting the body on my scroll saw works best. This approach minimizes the risk of tearout, a common problem when drilling after cutting. By drilling the hole before cutting, you can create a guide for the saw blade, making the cutting process more precise and straightforward.

However, other options exist besides drilling before cutting using a drill press. Horizontal boring using a Shopsmith is another approach that I want to explore.

Once you have cut the body, the opening still needs to be finished. This is where handwork comes in. I cut away space for the hook using files, rasps, and sandpaper. This process requires patience and a steady hand but also ensures the hook fits securely in the opening and moves easily.

Cutting the space for the tow hook is a crucial step in building a tow truck. While drilling the hole before cutting on a scroll saw may work best for some, horizontal boring using a Shopsmith can also be a viable option. Regardless of your preferred method, I must take your time and use the appropriate tools to ensure a precise and secure fit for the tow hook.

2024-03-07

Drilling The Opening For A Tow Truck Hook - 482847326

Subscribe to:

Post Comments (Atom)

-

Order Today Puzzle Pal s Hot Rods Minivans There’s something truly special about handmade toys—they’re crafted with care, designed to insp...

-

Harbor Freight Four Inch Ratcheting Bar Clamp/Spreader I use a lot of clamps. They are the first clamps of this type sold by Harbor Freigh...

-

Shop Odin's Toy Factory Shop Etsy As the holiday season approaches, it's the perfect time to start thinking about how to adorn your ...

No comments:

Post a Comment