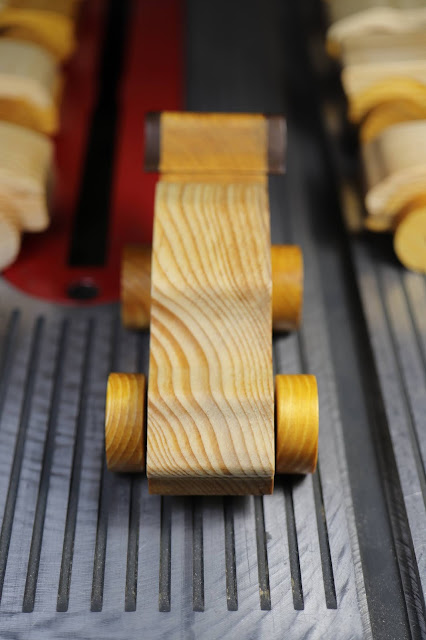

This Multipart post (part 9 of 13) is a series of photos I made after a

recent Speedy Wheels build. Speedy Wheels series is a series of handmade

wooden toy cars I made from 1-1/2-inch thick pine and trimmed with

walnut.

The car's body comprises two parts of 1-1/2-inch thick

wood I cut into two parts and finished separately with contrasting

colors of clear and amber shellac. The two parts are glued back

together, producing a car with a two-tone body with a clearly defined

line that is almost impossible to get otherwise.

I don't usually

make wheels; however, in this case, I did not have ready access to the

correct size flat/slab wheels. I dug through my cutoffs and found enough

pieces of wood to make a batch of wheels. Small wheels are an excellent

way to use all those small cutoffs toymakers accumulate.

I have

made many wheels over the years using hole saws. Hole saws produce a

rough cut wheel that requires a lot of sanding to get a smooth wheel.

This time I decided to try something different. Using Inkscape, I

created patterns for my scroll saw and cut all the wheels with the saw.

Cutting wheels with my scroll saw is much better than the old hole saw

method. The wheels still need sanding after cutting with the scroll saw,

but not anywhere near as much sanding as is required using a hole saw.

The sanding was mostly due to my inability to cut a perfect circle.

Using a simple jig, I sand the wheels perfectly round and the same

diameter. The patterns I used for these wheels are available in my Etsy

shop.

Another issue I have with making wheels with a hole saw is

that the hole size must be the drill bit's size in the hole saw arbor.

You can't have a smaller hole, and if you want a larger hole, you must

drill it after the wheels are cut. Cutting wheels with a scroll saw

allows you to use any size axle you want.

No comments:

Post a Comment