| |

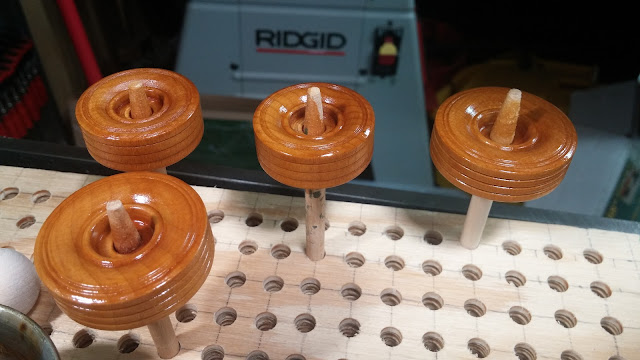

| Wheels For A Toy Car Curing After A Heavy Coat Of Amber Shellac |

My Shop Front Page

https://odinstoyfactory.etsy.com

Temperature and humidity are two important factors that can significantly affect the curing process of finishes. The curing process is the time it takes for a finish to completely dry and harden, and it is essential for achieving a durable and long-lasting finish. This blog post will discuss how temperature and humidity can affect finish cure times.

Temperature

Temperature plays a critical role in the curing process of finishes. Warmer temperatures will accelerate the curing process, while colder temperatures will slow it down. This is because the chemical reactions during the curing process are temperature-dependent.

When the temperature is too low, the curing process will take longer and may not even occur. Low temperatures can cause the solvents in the finish to evaporate too slowly, leading to a gummy or sticky finish. On the other hand, high temperatures can cause the finish to cure too quickly, leading to cracking, checking, and other defects.

The ideal temperature for curing finishes is typically between 65°F and 75°F. This temperature range allows the solvents to evaporate at an appropriate rate while allowing the finish to cure fully and develop a durable and long-lasting finish.

Humidity

Humidity is another important factor that can affect the curing process of finishes. Humidity is the amount of moisture present in the air, and it can significantly impact how quickly finishes dry and cure.

High humidity can slow down the curing process, as it can prevent the solvents in the finish from evaporating as quickly. This can lead to a finish that remains tacky or sticky for an extended period. On the other hand, low humidity can cause the finish to dry too quickly, resulting in a brittle finish and prone to cracking.

The ideal humidity for curing finishes is typically between 40% and 60%. This humidity range allows the solvents in the finish to evaporate at an appropriate rate while providing enough moisture to prevent the finish from becoming too brittle or prone to cracking.

Conclusion

In conclusion, temperature and humidity are two important factors that can significantly affect the curing process of finishes. To achieve the best results, paying attention to these factors and ensuring that the temperature and humidity levels are within the recommended range for the type of finish being used is essential. By doing so, you can achieve a durable and long-lasting finish that will look great for years.

#odinstoyfactory #handmade #woodtoys #madeinusa #madeinamerica

No comments:

Post a Comment