|

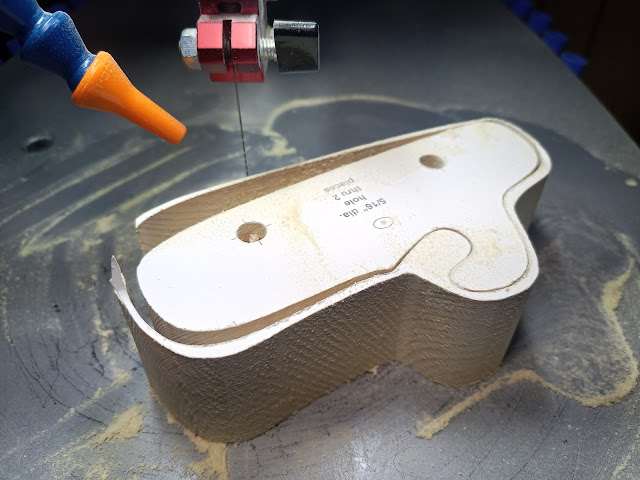

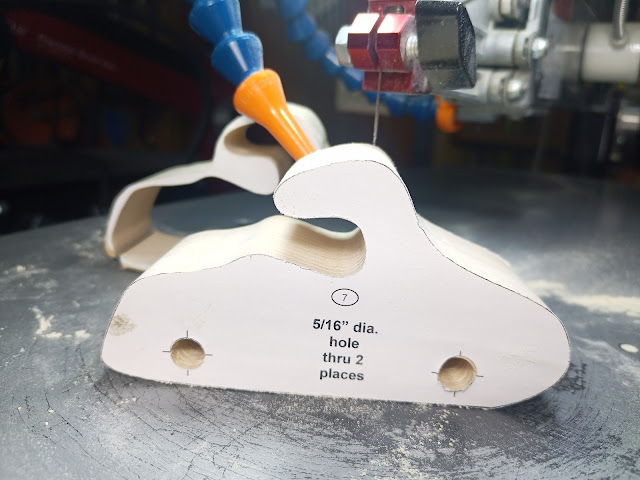

| Handmade wooden toy truck, Martin Motors antique car carrier. All parts are cut and ready for pattern removal and sanding. |

All of the parts are cut. Before I remove the patterns, I like to true up any spots on the edges that need it. I use a belt sander (6-inch and one-inch wide belts) for the flat areas and outside curves, a rotary tool, hand sanding, and sometimes files for tight inside curves. I have an oscillating spindle sander, but the smallest radius it can sand is 1/2 inch. Once this is done, I remove patterns and sand the sides. Leaving the patterns in place while sanding the edges helps me to detect flaws and not overshoot the edges of the pattern. Since these are cut on a scroll saw, the edge sanding at this point is more of a shaping operation than smoothing.

https://odinstoyfactory.com/1632377592/

#odinstoyfactory #handmade #woodtoys #madeinusa #madeinamerica